The robotics industry in Asia has strong growth driven by the Japanese, Korean, and Chinese markets, with the region leading robot deployment globally. Besides manufacturing use cases, robotics is now used in other sectors such as logistics, healthcare, and site inspections.

Singaporean startup Eureka Robotics is striving to build upon this growing interest in robotics and bring new innovations within Southeast Asia. The company was founded by Pham Quang Cuong and Hung Pham in 2018 as a spinoff from Nanyang Technological University (NTU) after a video of its original robot assembling an IKEA chair went viral.

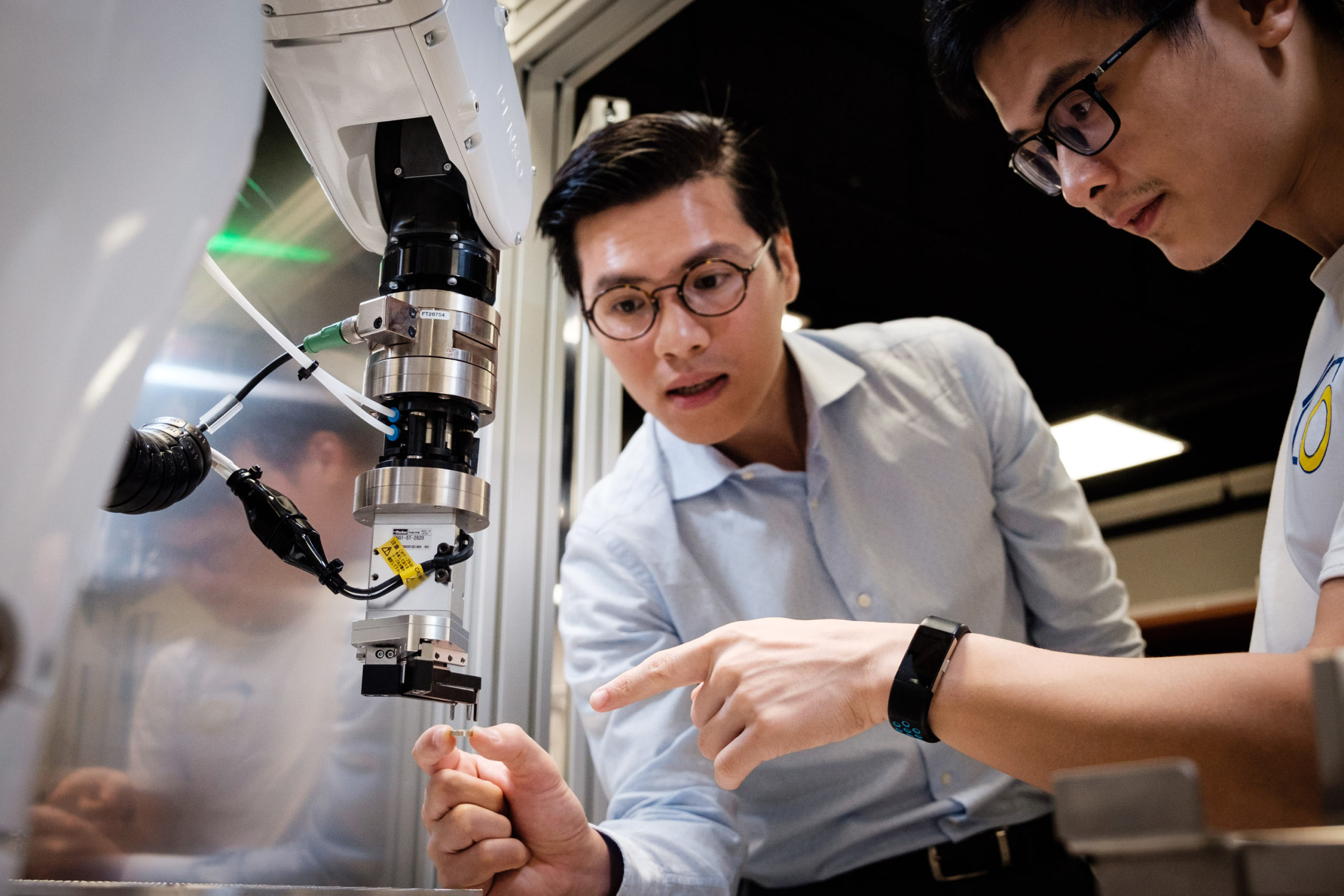

With products such as the optics manufacturing robot Archimedes being deployed in factories across Asia, the company has achieved steady growth and now has offices in Singapore, France, and China.

KrASIArecently spoke with Pham to discuss the challenges Eureka has faced as a startup and the future of robotic technology.

The following interview has been consolidated and edited for brevity and clarity.

KrASIA (Kr): What is the origin of Eureka Robotics?

Pham Quang Cuong (PQC): I came to Singapore in 2013 as an assistant professor at NTU. When I joined, our main research focus was on how to make industrial robots more intelligent by giving them touch, vision, and the ability to plan motions in real time. My first research grant proposal in 2014 was to build a robot that could assemble an IKEA chair and we managed to do just that in 2017. We shot a video and the paper was published in Science Robotics.

The main idea was to take a difficult task that requires a lot of human functions and set it as our objective. After the IKEA chair study was completed, we asked ourselves what we would do with the technology we had developed. We had the idea to take it to the factory floors. We decided to start a spinoff from NTU in 2018 to take all the technologies we developed at NTU and deploy them in factories.

Kr: As a robotics startup in Singapore, what challenges do you face? How did you overcome them?

PQC: The main difficulty for us here in Singapore is we don’t really have a huge internal market compared to the US, China, and Japan, which have tens of thousands of manufacturing companies. In the first two years of our existence, we were mainly focused on the beachhead market of optics manufacturing in Singapore. We now know everybody as there are probably 10 to 12 companies making lenses at a scale that would require robots.

Once we determined our beachhead market and started to sell our robots to those customers, it became a challenge because our domestic market is not big enough. We had to go international, which is why we started to expand to China last year. We had to find all sorts of ways to find distributors and system integrators overseas due to travel restrictions.

Another thing that we try to do is to partner with large companies, one of our partners is Denso, which will embed our software into their robots. We are also working with other Japanese companies to integrate our software with their instruments.

Kr: What does the robotics sector look like now?

PQC: There are a number of ways to do robotics. The traditional way is to teach a robot a given trajectory, and then it will repeat that trajectory all the time. You can achieve very high accuracy, but the motion is completely fixed. We call that low-agility, high-accuracy.

On the other hand, you have a number of companies making logistics robotics, like for packing. Those robots have higher agility, because they can adapt to new positions using a camera, but the tolerance is about 1 cm, which is fine if you want to pick up a box. That’s low-accuracy, high-agility.

Kr: Eureka Robotics uses high-accuracy, high-agility technology for your robots. How will this evolve and advance in the future?

It is difficult when you have to deal with environments that change. For example, Eureka’s robots pick up lenses. Imagine now that the lenses are scattered all around in random positions. The robot needs to adapt to the new positions, pick up the lenses, and put them in fixtures that are extremely tight. This is the combination of high accuracy and agility that makes this difficult to do.

Our technology development over the past few years has geared towards how we can reach extremely high accuracy with the right calibration, computer vision, planning, motion in real-time. We will keep pushing the frontiers of the accuracy that we can achieve, and how robots can adapt to different environments with very little customization or retraining.

One of the main difficulties is making the programming of these capabilities much easier for system integrator engineers. There’s a lot of things to do in terms of user experience and user interface. We are really focusing on how to make those sophisticated tools accessible to the general public.

Kr: Robotics has been advancing in industrial and manufacturing sectors. When will it become common for households?

PQC:We are moving to a stage where companies like us are developing robots that can adapt to some changes to your environment. We are not at a stage yet where the robot can be relied on in a completely unstructured environment such as a family home. I think there’s still at least five years to go before robotics technologies are able to tackle interesting tasks in a completely unstructured environment that requires some complex interactions. This is not just a robot moving around and showing an iPad, but robots that can do tasks like folding clothes or cleaning tables.

One area that needs to improve is the robot’s decision making. For example, to wipe the table, if there are still many objects on it, the robot must choose one object, remove it, clean the surface, then replace the item. There has been a lot of progress in academia and the technology of deep reinforcement with higher processing power.